SciELO - Brasil - Effect of ball to powder weight ratio on the mechanochemical synthesis of MoSi2-TiC nanocomposite powder Effect of ball to powder weight ratio on the mechanochemical synthesis of MoSi2-TiC

Effect of the variation of the ball to powder mass ratio, m b :m p , on... | Download Scientific Diagram

Effect of ball milling on the powder characteristics and welding mechanism of Mg2B2O5w/6061Al matrix composite - IOPscience

Effects of ball-to-powder diameter ratio and powder particle shape on EDEM simulation in a planetary ball mill - ScienceDirect

Minerals | Free Full-Text | Effects of Ball Size on the Grinding Behavior of Talc Using a High-Energy Ball Mill | HTML

Metals | Free Full-Text | Synthesis and Characterization of Copper-Based Composites Reinforced by CuZrAlNiTi Amorphous Particles with Enhanced Mechanical Properties | HTML

Sustainable Synthesis of High-Surface-Area Graphite Oxide via Dry Ball Milling | ACS Sustainable Chemistry & Engineering

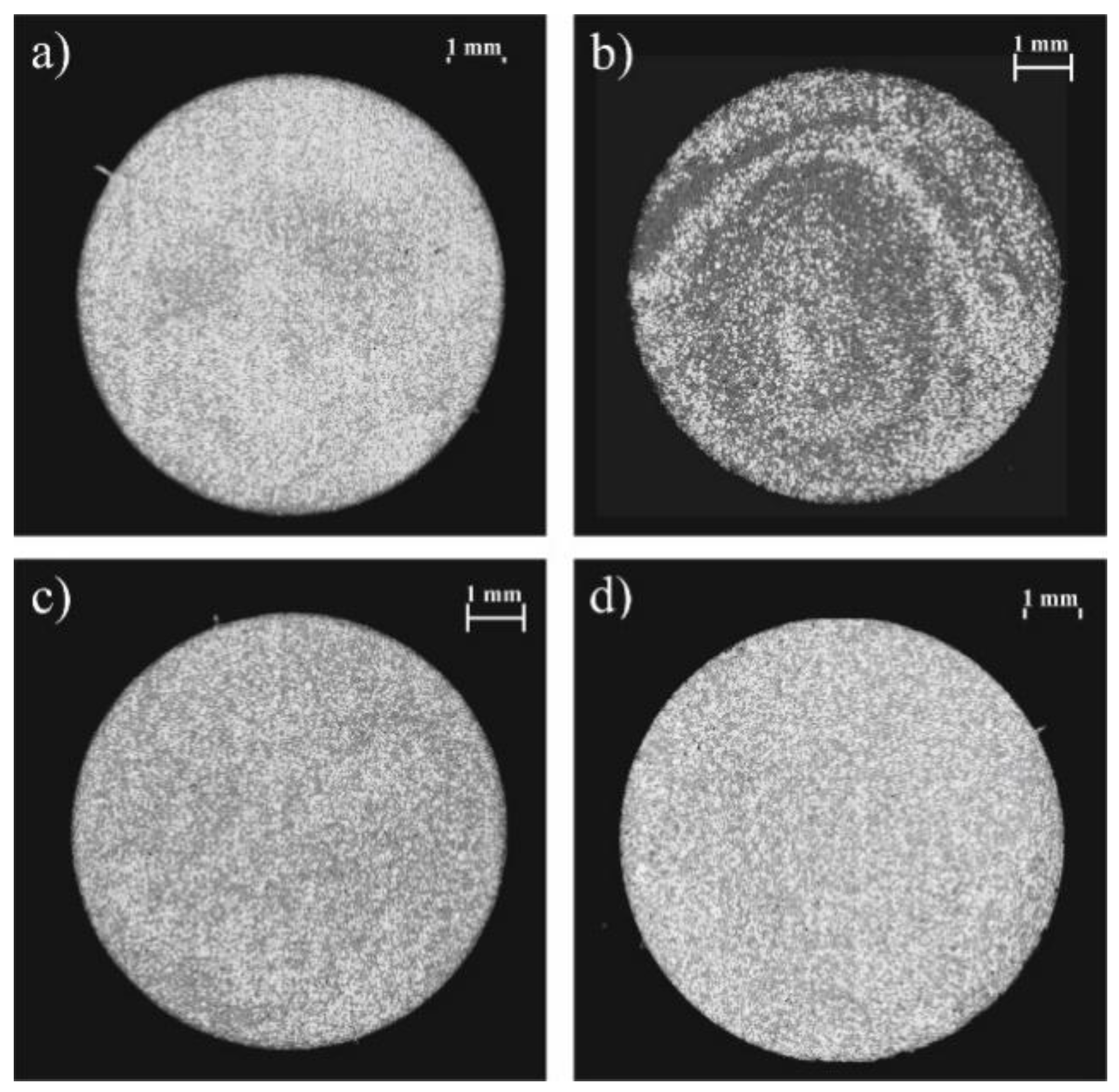

The ball to powder ratio (BPR) dependent morphology and microstructure of tungsten powder refined by ball milling - ScienceDirect

Milling map for a Ti±33at%Al powder relating the ball-to-powder ratio... | Download Scientific Diagram

The effect of ball to powder ratio on the processing of a novel Mo-Cu-Al2O3 composite - ScienceDirect

Optimum choice of the make-up ball sizes for maximum throughput in tumbling ball mills - ScienceDirect

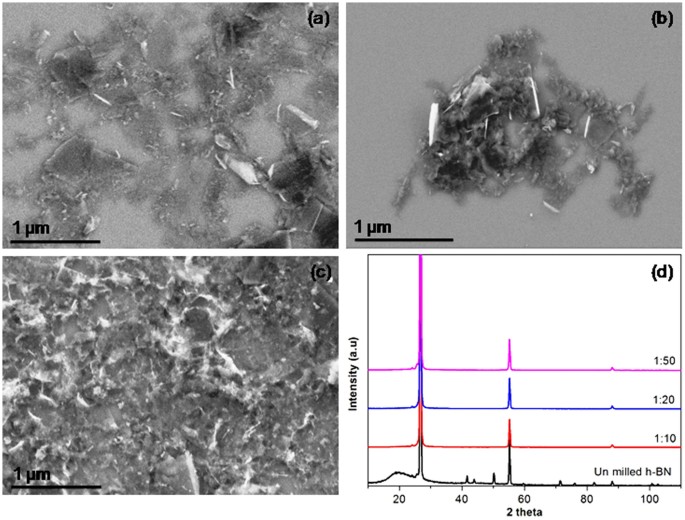

High-Efficient Production of Boron Nitride Nanosheets via an Optimized Ball Milling Process for Lubrication in Oil | Scientific Reports

Effect of ball size on steady state of aluminum powder and efficiency of impacts during milling - ScienceDirect

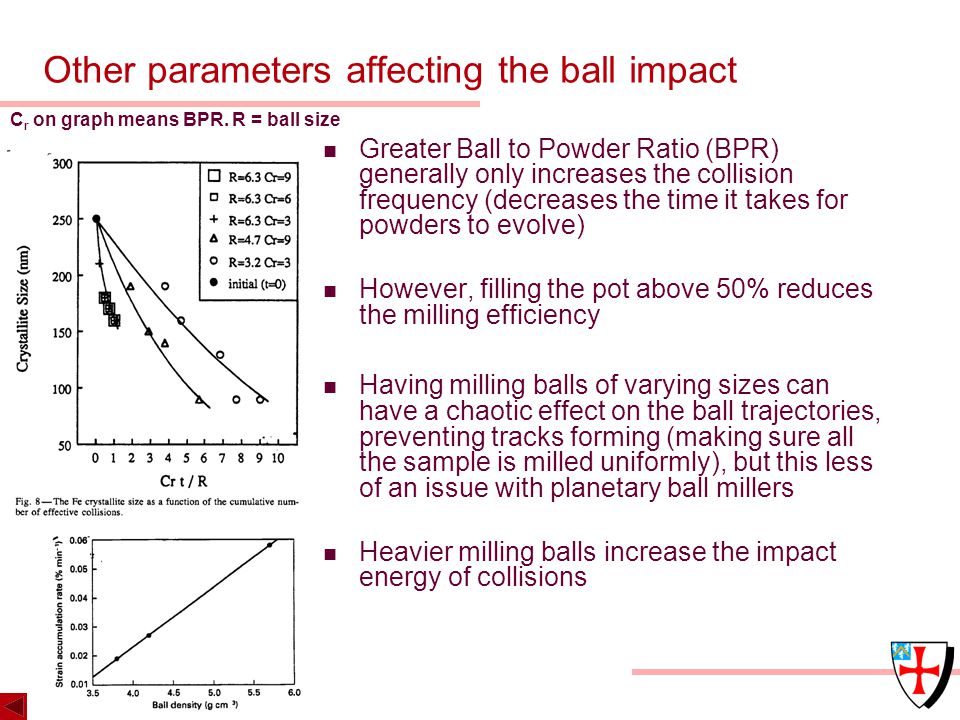

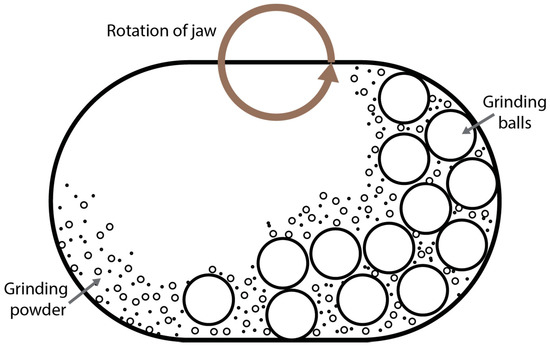

Why the ball to powder ratio (BPR) is insufficient for describing the mechanical ball milling process - ScienceDirect

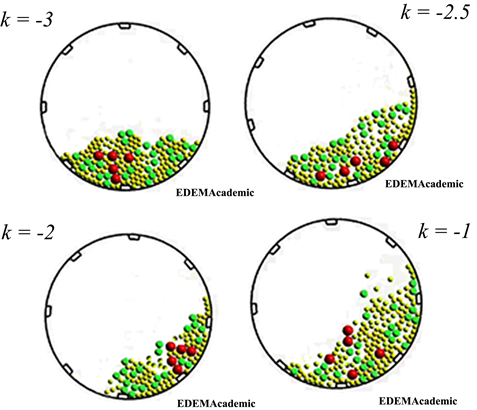

Effects of ball-to-powder diameter ratio and powder particle shape on EDEM simulation in a planetary ball mill - ScienceDirect

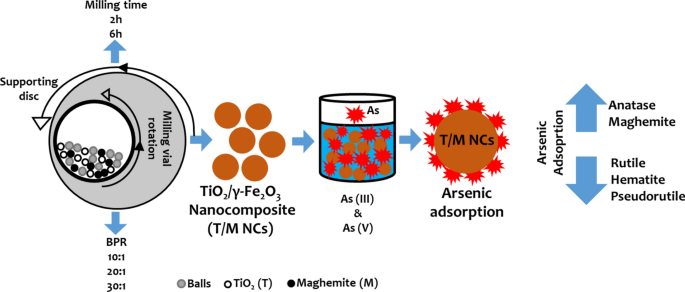

Mechanical activation of TiO2/Fe2O3 nanocomposite for arsenic adsorption: effect of ball-to-powder ratio and milling time | SpringerLink

Effects of ball-to-powder diameter ratio and powder particle shape on EDEM simulation in a planetary ball mill - ScienceDirect

The ball to powder ratio (BPR) dependent morphology and microstructure of tungsten powder refined by ball milling - ScienceDirect